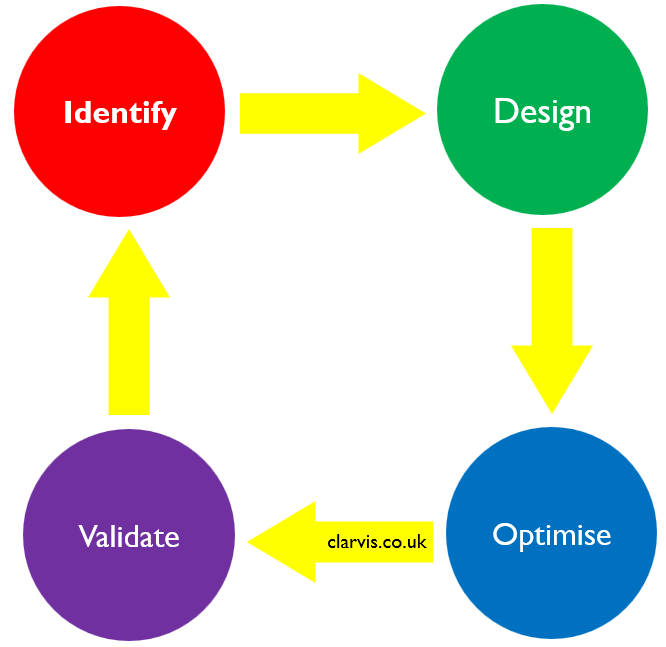

Design Engineers follow this design cycle to produce effective products.

The process allows checks to be made throughout the process to make sure that the final product does what it is supposed to and satisfies the needs of the client.

The cycle consists of four parts: Identify, design, validate and optimise. You might see the word "cyclical", all this means is that it is a process that goes around in a circle.

This is the first stage in the design cycle. At this stage the designer will communicate with the client to find out their requirements - what they want them to design.

They carry out research to get a better understanding of the problem and needs of the stakeholders.

A plan is written to guide the design process.

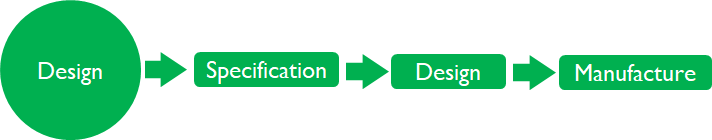

This is the second stage in the design cycle.

A specification is written which based on the information gathered in the identify stage. This sets out the rules that the designer will follow called a specification.

The designer will then create designs using methods such as hand sketches and CAD (Computer Aided Design).

A manufacturing plan is written describing how the product could be made.

The third stage involves making models to find out if the design is suitable. These models can be made out of things like card, foam and can be made on 3D printers.

A designer could come up with a design that it is not possible to make. Prototyping is needed to make sure that the designs can actually be manufactured .

Design problems can be identified early.

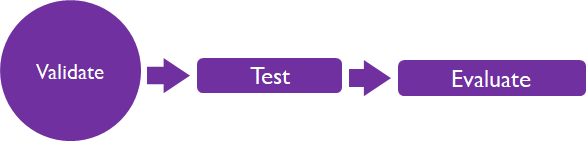

The fourth stage is validation. Validation is just another word for prooving.

At this stage the product is produced (made)

and tested to find out if it does what is required.

The product is evaluated against the design specification.

Any issues can be identified and if necessary modifications made before sale.