Vacuum forming is a method of forming plastics into a particular shape. The process involves heating up a thermoplastic, usually HIP (High Impact Polystyrene) and sucking it over a mould until is cools.

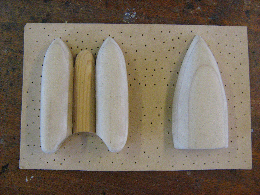

The first process involves manufacturing a mould. In school MDF is generally used but other heat-resistant modelling tools can be used.

It is important that the sides of the moulds are drafted otherwise it would be very difficult or impossible to remove the mould when the process is finished.

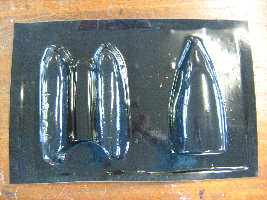

Not a brilliant example due to webbing!

1. Turn the former on and allow it to heat up

2. Place the mould onto the bed.

3. Place a sheet of thermoplastic on top of the seal.

4. Pull the frame down and clamp in place.

5. Pull the heater over the plastic sheet to soften it.

6. After about five minutes push the heater box back and check how soft the plastic is. It should dent slightly when pressed. If the plastic is too hot it will sag and smoke a little, it is unlikely that the process will work in this case. It ill be very hot!

7. Pull the lever on the right to raise the bed, pushing the mould into the plastic sheet. Turn the pump on.

8. Once cooled, riase the lever and the mould should lower back into the machine. It is now complete.